Have you ever stopped to think about how does a hinge works & how they make our lives easier?

Hinges are critical in connecting two objects and allowing them to rotate or pivot. These simple yet essential components can be found in countless applications, ranging from heavy-duty industrial machinery to delicate jewelry boxes.

While most of us may take hinges for granted and not give them a second thought, understanding how they work and the different types available greatly will enhance our appreciation for these unassuming yet vital pieces of hardware.

This article is all about hinges and how they work in the background to make some of the most essential objects in our lives operate smoothly.

What is a Hinge?

At its most basic level, a hinge is a simple mechanical device that joins two objects, providing them with the motion capability to swing open or close.

Hinges are made up of two leaves that are attached to the objects that need to be connected. These are usually made of metal although other materials such as plastic or steel can also be used.

Hinges are designed to be strong and durable and are often rated for a specific weight capacity or maximum load. This means that the hinge can support a certain amount of weight without becoming damaged or failing.

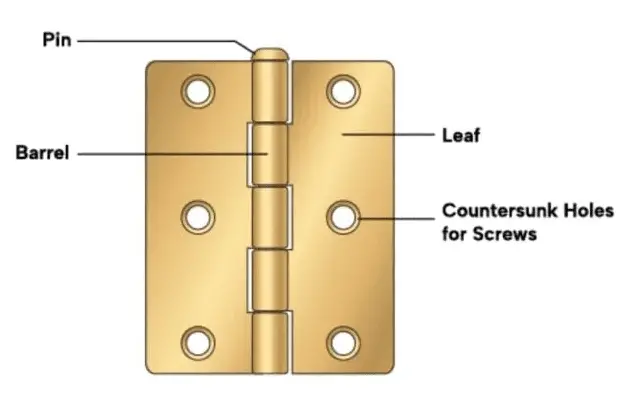

Anatomy of a Hinge

Hinges are intricate structures consisting of various components that come together to form one complete unit. All these parts work together to provide a durable & smooth pivot action.

Here’s a list of the different parts and their individual roles in ensuring proper operation – leaves, knuckle, and pin.

Leaf

The leaves are the flat, elongated sections of the hinge that are attached to the door or the frame.

The leaves provide the main support for the door and help to distribute its weight evenly across the hinge. They offer the mechanical advantage required for hinge joints to turn.

Knuckle (Barrel)

The knuckle is an integral component of the hinge – located in the center, it rotates around the pin and forms a ‘barrel’ with other knuckles present.

This barrel allows for the smooth operation of the hinge as it offers a pivot point for its movement.

Pin

The hinge pin is a cylindrical rod running through the knuckles, helping the two leaves of the hinge rotate and stay connected.

This durable component offers stability and strength to the construction of the overall hinge.

How Does a Hinge Work?

To understand how a hinge work, here is a brief overview:

Hinges function by linking two surfaces together, allowing them to rotate around an axis and turn open or close.

When a door or cabinet is opened or closed, the hinge’s components work together to facilitate movement.

As the door is rotated, the knuckle serves as the pivot point, allowing for smooth and stable movement.

The hinge pin holds the plates securely together and ensures that the door or cabinet remains attached to the hinge.

The leaves distribute the weight of the door or cabinet evenly across the hinge, preventing any undue strain or stress on the components.

Different Types of Hinges

There are several different types of hinges that you may come across, each of which has a unique purpose and function.

The most common types include:

1. Butt Hinge (Mortise Hinge)

This is the most commonly used type of hinge and is typically used for doors and cabinets.

The butt hinge or mortise hinge consists of two matching leaves that are joined together by a hinge pin and wide knuckles and can be either mortised.

Butt hinges are available in a variety of sizes so they are versatile for a range of applications.

2. Flush Hinge

Flush hinges are generally not as resilient as butt hinges and are best suited for lightweight objects or structures.

This type of hinge is designed to be mounted flush with the surface of the door or cabinet to create a clean and seamless look.

Flush hinges remain hidden within the interior of furniture. Their presence makes opening and closing these doors extremely easy.

3. Piano Hinge

Also known as a continuous hinge, a piano hinge is a long, narrow strip of metal that runs the entire length of a door or other object.

It is commonly used on musical instruments such as pianos as well as fold-down workbenches and large cabinets.

Piano hinges are known for their strength and durability and can support heavy loads without bending.

4. Spring Hinge

Spring hinges help close doors automatically once it has been opened. They compose of a spring that works to shut the hinge in place. This feature helps ensure doors do not stay open for too long making them practical & efficient.

With the adjustable hinges, you can control the speed of how quickly or slowly the door closes.

These hinges are commonly used in commercial settings such as offices and retail spaces where doors need to be kept closed for security or energy efficiency purposes.

5. Butterfly Hinge

Butterfly hinges are named for their distinctive shape, which resembles a butterfly when the hinge is open.

They are commonly used for decorative purposes such as on jewelry boxes and small cabinets.

Heavy-duty butterfly hinges are commonly used on large and heavy doors or gates that require a strong and durable hinge to support their weight.

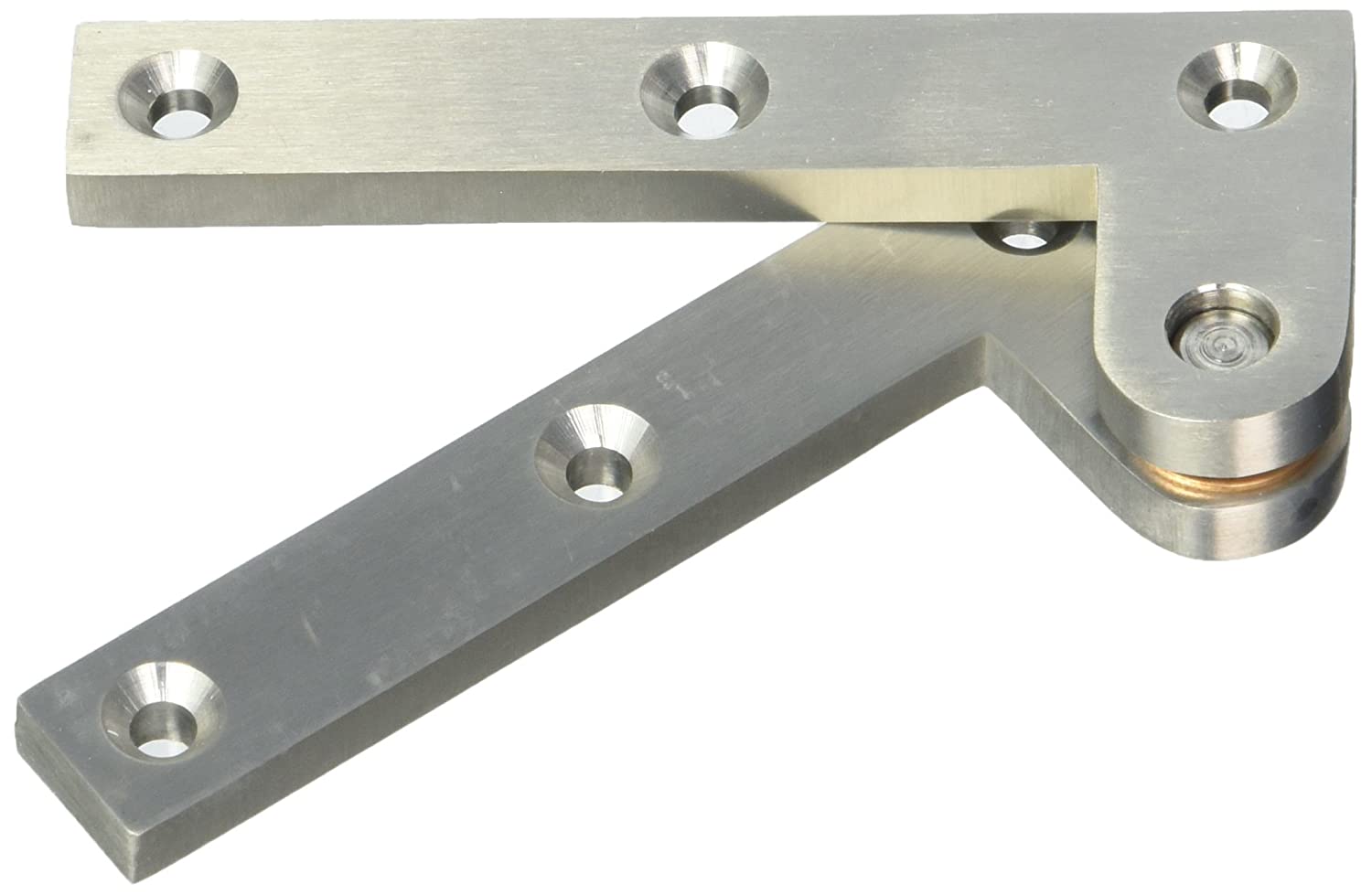

6. Knife Hinge / Pivot Hinge

Knife hinges also known as pivot hinges are a type of concealed hinge that is commonly used in cabinetry. The purpose of a knife hinge differs depending on the application for which it is used.

It is designed to be hidden from view when the door or cabinet is closed. A knife hinge can be employed to have a door lie snugly against its neighboring cabinet.

Some of The Applications of Hinges

Hinges are found in a vast range of applications across various industries. From doors and cabinets to cars and airplanes, hinges play a vital role in allowing movement and rotation.

Here are some examples of where hinges are commonly used:

1. Medical Industry

Hinges are an essential component of medical equipment and are especially critical for applications such as securing heavy vault doors or providing neutron shielding.

The solid construction and dependable sturdiness make them an integral part of any medical setup.

2. Automotive Industry

The automotive industry is another industry that heavily relies on hinges. Hinges are used in a variety of automotive applications such as car doors and trunk lids.

3. Military

Hinges play a vital role in the military and defense industry, appearing in vehicles, aircraft, weapons, and armored doors.

They must be able to withstand tough weather conditions & heavy usage as they are a significant part of military equipment.

4. Electronics

These mechanical devices can also be found in various electronic devices such as laptops where they allow the screen to be opened and closed while keeping it securely attached to the body of the device.

5. Petroleum & Natural Gas Facilities

Hinges are ubiquitous at facilities in the petroleum and natural gas sectors as they offer a lot of value when it comes to ensuring the safety and smooth operation of machinery and infrastructure.

These facilities often rely on heavy doors and gates that require sturdy hinges.

Given the high stakes involved in the petroleum and natural gas industry, hinges used in these applications must be made from high-quality materials and undergo rigorous testing to ensure they can withstand harsh environmental conditions and frequent use.

6. Aerospace Applications

Hinges are also widely used in the aerospace industry, particularly for the doors and swinging parts of aircraft.

Due to the extreme conditions of high altitude and temperature changes, hinges used in aerospace applications must be incredibly durable and able to withstand a wide range of forces and stresses.

7. Marine Industry

Marine environments can be harsh and corrosive making it crucial to use high-quality hinges that can withstand exposure to saltwater and other elements.

Hinges are used in a variety of marine applications like ship doors.

8. Construction Industry

Hinges are critical components in the construction industry and play a significant role in ensuring the structural integrity and functionality of various building elements.

Some common applications in the construction industry include:

9. Doors & Windows

Hinges are essential for attaching doors and windows to frames and allowing them to open and close smoothly.

Without hinges, doors, and windows would be stationary and not serve their intended purpose.

10. Gates & Fences

They are also used in gates and fences to attach them to their frames. Hinges used in these applications need to be strong, weather-resistant, and capable of handling heavy loads.

11. Furniture Industry

Furniture is another industry where hinges play a critical role. Hinges are essential components in most types of furniture including cabinets, wardrobes, desks, and tables.

Butt hinges are commonly used for cabinet doors while concealed hinges are popular for wardrobes and other types of furniture where a clean look is desired.

In addition to their functional purpose, hinges can also contribute to the aesthetic appeal of the furniture. Decorative hinges add a touch of elegance and charm to furniture pieces.

The role of hinges in these industries is absolutely essential. They provide flexibility and help facilitate the movement and rotation of different components, thereby making them vital for proper functioning and user experience.

Without hinges, it would be nearly impossible to open doors, windows, and cabinets. That’s why the availability of these simple pieces of hardware is so important for various uses.

Also, hinges must be carefully selected based on the specific application, taking into account factors such as load capacity, material, and environmental conditions.

A poorly chosen hinge can lead to issues such as squeaking or loose joints which can compromise the safety and functionality of the application.

Factors That Affect Hinge Performance

Several factors can impact how well a hinge works and understanding these factors can help you choose the right hinge for your needs and ensure its longevity.

Some of the key factors that can affect hinge performance include:

Installation

Improper installation of a hinge can lead to problems with its functionality. Hinges should be installed correctly and securely to ensure they function properly and do not become loose over time.

Material of the Hinge

Different types of hinges are made from a variety of materials such as brass, stainless steel, aluminum, and plastic, among others.

The material chosen for a hinge can impact its strength, durability, and resistance to corrosion, rust, and other forms of wear and tear.

For instance, brass hinges are a popular choice for their strength and resistance to corrosion. Stainless steel hinges are also durable and resistant to changes in temperature. Aluminum hinges are lightweight and resistant to corrosion.

On the other hand, plastic hinges are typically used for lightweight applications, such as toy boxes or small cabinet doors, due to their low cost and ease of use.

However, they may not be as durable or long-lasting as metal hinges.

How Frequently Hinges are Used?

The more a hinge is used, the more wear and tear it will experience. Over time, this can cause the hinge to become loose, wobbly, or even break. It is essential to choose a hinge that is designed for the frequency of use it will experience.

Depending on the number of uses per day, there are three categories of doors:

- Low

- Medium

- High Frequency

If a door is used less than 10 times a day, it falls in the low-frequency group; those that are accessed between 10 to 24 times daily are categorized as medium-frequency doors; while those with more than 25 uses per day are considered high-frequency entries.

Maintenance Practices

Proper maintenance greatly extends the life of a hinge. This includes lubricating the hinge regularly, tightening any loose screws, and cleaning it to prevent the buildup of dirt and debris.

Neglecting maintenance can cause the hinge to become stiff or corroded, impacting its performance.

Environmental Factors

The environment in which the hinge is installed can also impact its performance. If the hinge is exposed to moisture or extreme temperatures, it may become damaged or corroded over time.

Weight of the Furniture

The weight of the door or cabinet is one of the most important factors to consider when choosing a hinge.

If the hinge is not strong enough to support the weight of the door, it can become damaged. It is important to choose a hinge that is rated for the weight of the door or cabinet it will be attached to.

Calculating the right weight capacity for your furniture or doors depends on both how often they are used and the weight of the door.

This should give you an idea of whether standard or heavy-duty hinges are needed to provide maximum support.

Key Takeaways

Different hinge designs, sizes & functions offer various advantages for specific purposes. Knowing the various types of hinges and their applications can help you make an informed decision when selecting the right one for your needs.

Whether you’re working in construction, automotive, furniture, or any other industry that requires hinges, selecting the right hinge for the job makes all the difference in achieving optimal performance and functionality.

As such, it’s crucial to understand the different types of hinges available and how they work.

We have broken down the fundamentals of how a hinge works, detailing its parts such as the pivot point, the hinge pin, and other components that work together to facilitate smooth movement of the door.

Knowing the basic mechanics of how a hinge works and the different components that contribute to its functionality is essential in making an informed decision.

Furthermore, understanding the factors that can affect the hinge’s performance is crucial in ensuring its longevity and optimal operation.