The use of glue dates back to ancient civilizations. Ancient Romans and Greeks used a type of glue made from animal hides and fish bones for gluing thin layers of boards.

The first synthetic glue or adhesive was developed in the early 20th century. In the 1950s, epoxies, neoprenes, and acrylonitrile became widely available and are now commonly used woodworking types of glue.

In this article, we will explore the various types of wood glue and when to use them in different woodworking projects.

What is a Wood Glue?

Wood glue is a type of adhesive that is specifically formulated to bond pieces of wood together. Such adhesives are vital materials for any woodworking project as they help to hold pieces of wood securely in place and ensure that the finished project is extremely strong and durable.

Different Types of Wood Glue & Their Uses?

Several wood glue types are available today and all of them are best suited for certain types of woodworking projects or processes.

When picking out wood glue, consider the specific requirements of the project and choose a glue that is best suited to meet those requirements. Some types of adhesives you can use for your woodworking projects are:

1. Aliphatic Resin (Yellow Glue)

Aliphatic resin also called carpenter’s glue is a synthetic resin that’s used to bond together pieces of wood. It has a heavy creamy consistency, which enables it to be spread evenly over surfaces without leaving behind a residue as other adhesives do. It is an alternative to other glues like cyanoacrylate or epoxy glues.

Aliphatic resin glue is made from aliphatic compounds. This glue type is usually used in the furniture industry.

What are the benefits of Aliphatic Resin?

Aliphatic glue is resistant to water, which makes it suitable for projects that will be subjected to high levels of humidity like products used in damp environments.

The glue has a flexible nature so it withstands movement and expansion without breaking the bond. It is ideal for use in applications where the materials being bonded are likely to expand or contract due to temperature changes or other factors.

Aliphatic resin is easy to apply and work with so it is used by both professionals and DIY enthusiasts.

What are the disadvantages of Aliphatic Resin?

Aliphatic glue is generally more expensive than some other types of glue so it may be less cost-effective for some users. Secondly, the material is not suitable for outdoor use.

When to use Aliphatic Resin?

Aliphatic glue is a versatile material often used in woodworking for its durability and strong bonding qualities; it is great for projects where a high level of strength is required.

The resin is often used for model boat making.

2. Animal Glue

Animal glue, also known as hide glue, is a type of adhesive that is made from the prolonged boiling of animal hide or bones until the protein-rich material is reduced to a gel-like substance.

It has been used for centuries in a variety of applications, including woodworking, bookbinding, and the construction of musical instruments.

Animal glue has been made from various animals including horses, cattle, rabbits, and fish. Horses in particular have a long history of use. And that’s why you hear stuff like “sent to the glue factory” when a horse is put to sleep.

The use of animal glue, however, has declined in recent years due to the availability of synthetic alternatives that are more effective and affordable. Also, animal glue is not as strong as some other wood adhesives like epoxy or polyurethane.

What are the benefits of Animal glue?

One of the benefits of hide glue is that it is reversible, meaning that it can be easily broken down and removed with heat. This makes it a good choice for antiques and other delicate items that may need to be repaired or disassembled when a mistake is made. Think of it as “Ctrl Z” in woodworking.

What are the disadvantages of Animal glue?

Most woodworkers avoid animal glue because it is sensitive to moisture. When animal glue is exposed to water or high humidity, it can absorb the moisture and become soft and pliable again, which can cause it to lose its adhesive strength and cause joints to loosen.

When to use Animal glue?

Animal glue is an ideal choice for any project that involves disassembly because it is reversible. Antique furniture is made of beautiful materials that may need to be taken apart, repaired, and maintained. Hide glue is perfect for this because it’s reversible and has a quick drying time.

3. Casein Glue

Casein glue is a type of adhesive made from casein, a protein found in milk. It is a natural and biodegradable adhesive that has been used in ancient times for early aviation. Casein glue is typically made by combining casein with an alkaline solution. The paste is then heated until it thickens and becomes the desired consistency for use as an adhesive.

Although animal glues are most often used for wood bonding, it is sometimes better to use a casein-based glue. Casein glues are more moisture resistant than other glues and the aging properties are superior too. It also aids with the adhesion of paints and coatings.

What are the benefits of Casein glue?

Casein glue is made from natural ingredients and is generally considered to be non-toxic. So, it is fitting for use in food-related applications like cutting boards and other products that may come in contact with humans or animals. In addition to that, the adhesive is moisture-resistant; it is durable even under damp conditions.

For woodworkers who are environmentally conscious, casein glue is an eco-friendly choice.

What are the disadvantages of Casein glue?

Casein glue has a relatively short shelf life compared to other types of adhesives. It easily spoils or becomes ineffective if not stored properly as it can be attacked by bacteria. Some people may be allergic to casein, a protein found in milk, so the glue may not be right up their street because of their milk allergy.

Also, the glue is not ideal for all types of materials and applications as it tends to get too stiff easily.

When to use Casein glue?

The casein-based adhesive is mainly used in the food industry, specifically, the beverage industry for labeling and packaging. It can be used to bond wood together to make a cutting board since it is a natural, non-toxic adhesive that is resistant to water.

4. Cyanoacrylate Adhesive

Cyanoacrylate adhesive, also known as “super glue,” or “crazy glue” is a strong, fast-acting acrylic resin. The adhesive becomes activated when there is moisture present on the surface. If applied to a dry surface, it won’t glue the wood pieces.

What are the benefits of Cyanoacrylate glue?

One of the main advantages of cyanoacrylate glue is its ability to bond almost instantly when it comes into contact with a moist wooden surface. It is a useful choice for applications where a fast-curing adhesive is required.

The adhesive is also known for its excellent strength and durability as it creates strong, permanent bonds that are resistant to water and heat.

What are the disadvantages of Cyanoacrylate adhesive?

One major disadvantage of cyanoacrylate adhesive is it can form strong bonds with your skin if it comes in contact with it. It will be difficult to get it off your skin and can cause skin reactions. To safely dissolve the adhesive from your skin, use nail polish remover/acetone.

Another drawback of cyanoacrylate is that bonding wood pieces may be compromised due to a lack of moisture. Finally, the gluing material is not suitable for all surfaces and can be resisted by substances like heat-resistant plastics which can keep moisture at bay.

When to use Cyanoacrylate glue?

Cyanoacrylate glue is compatible with a wide range of materials, including metal so it creates bonds between metal and wooden surfaces. Its instant-use nature makes it ideal in certain situations where clamping is burdensome.

And if you have a cracked or broken object that needs to be repaired, cyanoacrylate glue can be an effective solution.

5. Epoxy Resin

Epoxy glue is a type of adhesive that is made from a two-part system consisting of a resin and a curing agent. When these two parts are mixed together, they create a strong, durable bond that can be used to join wooden surfaces.

The process of curing is done by the chemical reaction between the resin and the curing agent so it does not require pressure.

What are the benefits of Epoxy Resin?

Epoxy resin is resistant to water and moisture because it has a chemical structure that is not soluble in water. It also has excellent adhesion properties hence, it is useful for metal coatings.

Epoxy glue is resistant to wear and tear and it is known to hold out against harsh conditions.

What are the disadvantages of Epoxy Resin?

It can release fumes when it cures and inhaling these fumes can be harmful when inhaled in large quantities. Exposure to epoxy fumes can cause respiratory illnesses like asthma.

To minimize the risk of inhaling the resin fumes, do well to work in a well-ventilated environment. This helps to deplete the fumes when using the adhesive. If possible, wear a highly protective mask or respirator.

When to use Epoxy Resin?

Epoxy resin can be used as an electrical insulator in electrical and electronic applications. It is also used as a coating for surfaces like floors and tables and even metals. Due to its adhesive qualities, the glue can bond structural components and can also be used to repair damaged materials.

6. Phenol Formaldehyde Resin

Phenol formaldehyde resin is the first synthetic adhesive to be sold for commercial purposes. The synthetic polymer is created by the polymerization of phenol and formaldehyde.

What are the benefits of Phenol Formaldehyde Resin?

It is a low-cost glue for chipboard and plywood. The resins have no melting point so they are perfect for high-temperature applications.

Phenol formaldehyde glue has good thermal insulation as it has high heat resistance and low thermal conductivity.

It is a cost-effective choice for many applications and can be easily molded into unique and complex shapes.

What are the disadvantages of Phenol Formaldehyde Resin?

This glue can release formaldehyde gas, which can be harmful to humans in high concentrations. As a result, it is of utmost importance to follow proper safety precautions when working with it.

Phenol formaldehyde resin is not very resistant to certain chemicals, including alkalies. Additionally, it can be irritating to the skin or eyes.

When to use Phenol Formaldehyde?

Phenol formaldehyde (PF) resin is commonly used in the production of plywood. PF resin improves the strength and durability of the wood as it gets applied to the wood veneers as a liquid and is allowed to cure while the sheets are pressed together.

The curing process involves applying heat and pressure to the sheets, which helps to ensure that the resin fully bonds with the wood.

7. Polyvinyl Acetate (PVA)

PVA is a popular type of glue for woodworking due to its easy and cheap application. It is non-toxic, PH neutral, and safe. Its application requires just a few minutes, so it’s perfect for beginners and people who are pressed for time.

Polyvinyl acetate is an easy glue to work with: you can use it on almost any kind of material, including cardboard, plastic, leather, and metal foil.

You can use it to repair torn or broken pieces of wood or to join two pieces of wood together. To get the most out of your PVA glue, make sure that all joints are fitting snugly and clamped during the curing process.

What are the benefits of PVA?

PVA has many benefits, including its fast absorption into porous materials like wood forming a strong bond as it dries. Because it’s easy to use, you shouldn’t have any problems creating a quality project without stress.

Polyvinyl Acetate dries completely, leaving a clear, uniform, and consistent surface that is easy on the eye. The material does not emit any odor or toxic fumes.

What are the disadvantages of PVA?

PVA is not water-proof. Once it dries it will dissolve if it comes in contact with water. It is not resistant to bacteria, which means that it can be easily broken down and destroyed by microorganisms.

Applying varnish over it would not be effective but you can paint over it once it has dried. Just make sure to allow the PVA sufficient time to dry and cure before applying the paint.

When to use PVA?

Most often, PVA is used as an adhesive for wood. It is likely to come in handy when you have some wood pieces that you’d like to glue together. It is also used as wood filler by mixing equal parts of sawdust into it.

PVA is one of the well-liked adhesives used as a high-performance sealant that can help prevent moisture damage on wooden items.

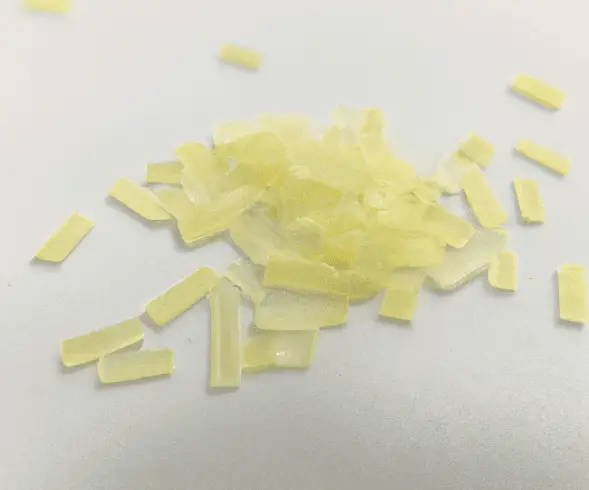

8. Urea-Formaldehyde

Urea-formaldehyde resin is a low-cost material that is resistant to impact, abrasion, and microorganisms. The white powder is dissolved in cold water for use. It is best used at most three hours after mixing. Urea-formaldehyde’s strength makes it very desirable in many applications.

What are the benefits of Urea-Formaldehyde?

Most plywood manufacturers use urea-formaldehyde glue when assembling their products. The urea-formaldehyde glue is relatively inexpensive and it is easy to work with, quick to apply and produces strong adhesion over time.

What are the disadvantages of Urea-Formaldehyde?

The use of urea-formaldehyde resins is a major source of formaldehyde exposure to consumers. Urea-formaldehyde can be affected by moisture or heat, start to break down, and end up releasing formaldehyde. Formaldehyde is a colorless and extremely toxic gas with a pungent odor. The gas can cause myeloid leukemia and rare cancers.

When to use Urea-Formaldehyde?

Urea-formaldehyde resin is an important component for wood-based panels. It is used to bond particle boards, plywood, and veneer-related projects.

Conclusion

Wood glue is an important material for woodworking because it is indispensable to woodworkers. It is one sure way to repair cracks or reattach loose or broken pieces. Wood glue is also good for assembling a project instead of using nails or screws. Some woodworking joints rely on glue to hold their position.

All of the glues mentioned above can be used in several woodworking applications. However, a very common type is PVA, which is great to use in almost all projects, and it’s one of the easiest glues to apply.